VA Project Pictures

Please hover over/touch images to see directional arrows:

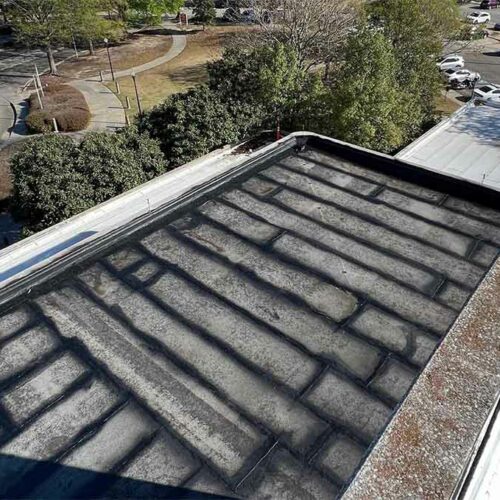

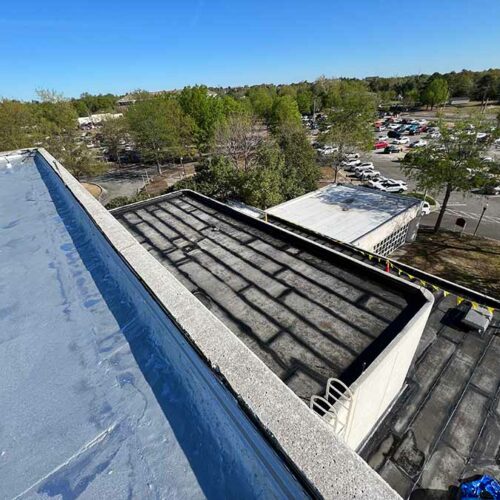

Site 1: Augusta VA in Georgia

Existing roof deck pressure washed and cleaned ready for IPP restoration. Roofs are restored in-place; this prevents tons of construction waste from filling local landfills, meeting federal requirements for waste reduction. (EO/FAR/VAAR)

Existing roof deck pressure washed and cleaned ready for IPP restoration. Roofs are restored in-place; this prevents tons of construction waste from filling local landfills, meeting federal requirements for waste reduction. (EO/FAR/VAAR) All seams, curbs, flashing, transitions, and drains are sealed with IPP spray grade dual component rubber emulsion rubberized membrane.

All seams, curbs, flashing, transitions, and drains are sealed with IPP spray grade dual component rubber emulsion rubberized membrane. Rubberized membrane used around roof drains with reinforced fabric embedded.

Rubberized membrane used around roof drains with reinforced fabric embedded. Rubberized membrane used around roof drains with reinforced fabric embedded.

Rubberized membrane used around roof drains with reinforced fabric embedded. Rubberized membrane used around roof drains with reinforced fabric embedded.

Rubberized membrane used around roof drains with reinforced fabric embedded. Installing one-way vents in the deck to allow pressurized gases that can build up under the roofing membrane to escape/off-gas. Reinforcing fabric is applied into the membrane to reinforce the joints/seams; the final coatings create a seamless product.

Installing one-way vents in the deck to allow pressurized gases that can build up under the roofing membrane to escape/off-gas. Reinforcing fabric is applied into the membrane to reinforce the joints/seams; the final coatings create a seamless product. One-way vent sealed into the deck and top coated with B-1008.

One-way vent sealed into the deck and top coated with B-1008. All deck seams are sealed with dual component rubberized membrane.

All deck seams are sealed with dual component rubberized membrane. All deck seams are sealed with dual component rubberized membrane.

All deck seams are sealed with dual component rubberized membrane. Roof prepared for base coat application overtop of sealed seams. The 5gal buckets are B-2008 urethane elastomeric gray base coat.

Roof prepared for base coat application overtop of sealed seams. The 5gal buckets are B-2008 urethane elastomeric gray base coat. Base coat B-2008, sealing the entire roof deck before top coating with UV stable Highly Reflective White B-1008 cold applied elastomeric urethane coating.

Base coat B-2008, sealing the entire roof deck before top coating with UV stable Highly Reflective White B-1008 cold applied elastomeric urethane coating. Base coat B-2008, sealing the entire roof deck before top coating with UV stable Highly Reflective White B-1008 cold applied elastomeric urethane coating.

Base coat B-2008, sealing the entire roof deck before top coating with UV stable Highly Reflective White B-1008 cold applied elastomeric urethane coating. Base coat B-2008, sealing the entire roof deck before top coating with UV stable Highly Reflective White B-1008 cold applied elastomeric urethane coating.

Base coat B-2008, sealing the entire roof deck before top coating with UV stable Highly Reflective White B-1008 cold applied elastomeric urethane coating. After B-2008 base coat application, curbs and penetrations are detailed with B-1008 white topcoat.

After B-2008 base coat application, curbs and penetrations are detailed with B-1008 white topcoat. White top coat on parapet walls and flashing

White top coat on parapet walls and flashing Detail work around penetrations, curbing, equipment prior to final white top coating.

Detail work around penetrations, curbing, equipment prior to final white top coating. Detail work around penetrations, curbing, equipment prior to final white top coating.

Detail work around penetrations, curbing, equipment prior to final white top coating. B-1008 white top coat application overtop of B-2008 urethane elastomeric. Employees are using a “super spreader” to evenly distribute product and back roll to desired thickness.

B-1008 white top coat application overtop of B-2008 urethane elastomeric. Employees are using a “super spreader” to evenly distribute product and back roll to desired thickness. Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements.

Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements. Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements.

Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements. Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements.

Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements. Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements.

Final top coating with B-1008 white elastomeric urethane, sealing the entire roof deck and providing solar reflectance to reduce heat island effect and promote energy cost reductions. This meets federal sustainability requirements. Final review will include detailed walk-thru inspection, detailed coating applications across all sections of the roof decks, and Warranty Certification.

Final review will include detailed walk-thru inspection, detailed coating applications across all sections of the roof decks, and Warranty Certification.