Acrylic coatings are popular for a reason.

They are cheap, seem easy to install, and can potentially have an adequate lifespan.

For all of these reasons, acrylic coatings are a popular choice for building owners on a tight budget.

That being said, acrylic coatings have some critical weaknesses you should be aware of.

More, while they seem affordable at first, acrylic coatings come with hidden costs.

In this article, Instacoat Premium Products is going to explain 5 of the reasons acrylic coatings fail, and how they can actually cost you MORE money in the long term.

1. Poor Drainage System

Acrylic systems require a drainage system in optimal condition.

By having a drainage system working efficiently, you can improve the overall performance of an acrylic coating system.

It will increase its longevity and avoid further roofing issues, increasing its lifespan to 20 years or more.

To discover more about commercial roof drainage systems, click here.

2. Ponding Water

Although manufacturing formulations for acrylic coatings have evolved over the years, the problem of ponding water still remains.

As you may know, acrylic restoration systems are water-based, which means they are not the best solution if you live in a rainy area.

They will eventually break down when exposed to ponding water for extended periods.

Standing water over the roof surface for more than 48 to 72 hours will ultimately cause the system to fail.

To discover more about ponding water on a commercial roof, click here.

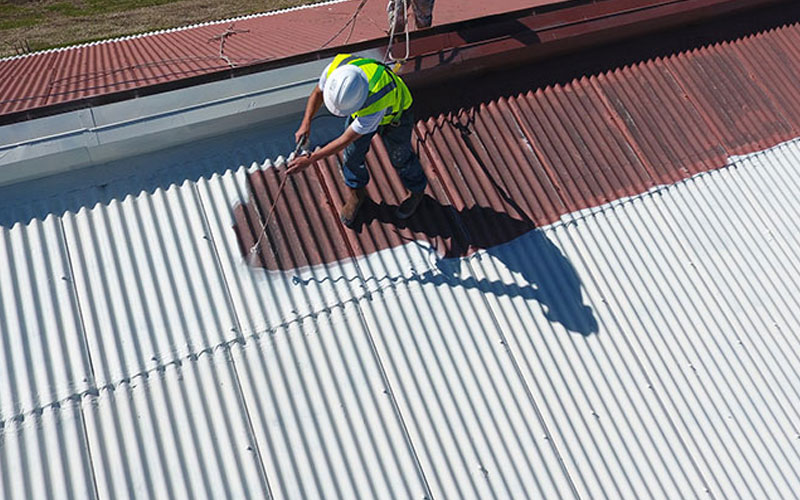

3. Improper Installation

Acrylic coatings are easy to apply. However, this often leads to not following the installation guidelines correctly.

While modern restoration systems such as Silicone or Urethane require only one coating application, the thickness of acrylic coatings requires at least two coats.

Because acrylic systems require two coats at the bare minimum, they have a hidden cost that is not obvious at first glance.

Further, due to their tendency to break down in ponding water, an acrylic coating requires each roof element to function at near-perfect efficiency to avoid failure.

Once again, this is a hidden cost you must consider when choosing acrylic coatings for your roof.

Acrylic coatings require two coats at the bare minimum.

4. It cannot Be Applied During Extreme Cold

As we mentioned before, acrylic coatings are water-based, and water freezes at 32 degrees Fahrenheit.

So, keep in mind that installing an acrylic coating system during winter will not be possible in many areas of the country.

Acrylic systems are not only limited by the cold; they are also prone to failure in areas with excessive humidity or extreme heat.

5. Blisters and Dust Particles

The installation should also include a complete roof surface cleaning and preparation.

If the underlying substrate is not thoroughly cleaned, the dust in between can not allow full adhesion, causing roof blisters and bubbles over time.

To discover what causes a roof to blister and potentially fail click here.

A Silicon Roof Restoration System Is a Premium Product and a Better Alternative than An Acrylic Coating Product

Contact Instacoat Premium Products and ask for a better roof restoration solution.